|

|

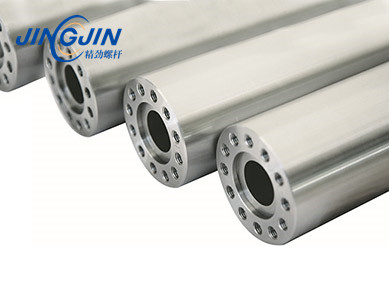

we have deeply researched on the barrel and screw for the special engineering plastic,for now much of engineering plastics add the calcium,kaolin,red clay, silica or add Glass fiber, carbon fiber, boron fiber and halogen free plastic to make the original plastic much better to adapt the specific plastic products.On the other hand, it may make the screw and barrel wear and corrosion quickly, In order to solve this problem,we have invented a kind of special alloy powder,whose ingredient contains 25%~50% Wc tungsten carbide.It makes the service life of screw and barrel much more longer than the other kinds of bimetallic screw and barrel.

| matenial | Grade A Wc-10 tungsten carbide alloy | Grade B Ni 20 Ni-based alloy | Grade C Fe -30 Fe-based alloy |

| Processing range : | Inner dia.: ∅16mm-∅450mm,effective length 9000mm | Inner dia: ∅16nm-∅450nm.effective length 9000mm |

Inner dia. : ∅16mm-∅450m.effective length 9000mm |

| Processing technique: |

Centnifugal casting ,allay layer reach 1.5mm-2mm one side, maxmumreach 3mm-6mm one side |

Centrifugal casting, alloy layer reach 15mm-2mm one side,maxinumreach 3mm-6mm one side |

Centrifugal casting, alloy layer reach 1.5mm-2mm one side,maxinumreach 3mmn-6mm one side |

| Alloy powder composition | Wc(50%-60%),C,Si,Cx,B,Ni,Mo,Co,etc | N,C,Si,Cr, B,Mo,Co,Wc(20%-25%).etc | Fe,C,Si,Cr, B,Mo,Ni, Co,etc |

| The index of hardness | HRC62-65,the service life of5-6 times longer than the nitnide one | HRC60-63.the service life of 4-5 times longer than the nitnide one |

HRC59-61the service life of3-5 times longer than the nitnide one |

| Charactenistics of alloy powder |

High wearing resistance,high corrosion resistance and high temperature resistance | High corrosion resistance,high wearing resistance and high tenperature resistance |

Wearing and corosion resistance |

| Application | Nylon plus 30% - 50% glass fiber; bakelite, mgnetic powder, ceranic powder. aluninum magnesiumpowder, iron powder, LCP and halogen- free flame retardant plastic | PE, PC, PVC, LCP, acrylic, transparent plastic, halogen fee flame retardant plastic, corrosion resistance ofresin plastic, etc |

Nylon plus 10% -30% glass fber, PC plus glass fber, PVC plus calciumpowder, recycled plastics processing. etc |

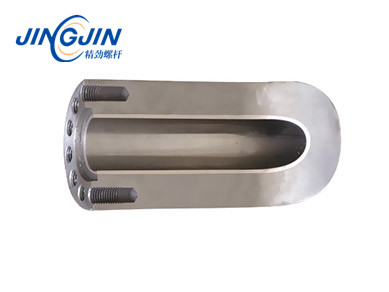

Bimetallic barrel for extrusion machine

| maternial | Grade A Wc-10 tungsten carbide alloy | Grade C Fe-30 Fe-based alloy |

| Processing range | Inner diameter : ∅ 16mm-∅450mm,effective length to 9000mm | Inner diameter : ∅ 16mm-∅450mm effective length to 9000mm |

| Processing technic | Centrifugal casting,alloy layer reach 1.5mm-2mmone side maximum reach 3mm-6mmone side | Centrifugal casting, alloy layer reach 1.5mm-2mmone side,maximumreach 3mm-6mm one side |

| Alloy powder conposition | Wc(50%-60%),C,Si,Cr, B,Ni,Mo.Co,etc | Fe.C,Si,C,B,Mo,Ni, Co,etc |

| Index of hardness | HRC62-65,the service life of5-6 times longer than the nitnided one | HRC59-61,the service life of3-5 times longer than the nitnided one |

| Charactenistics of alloy | High wearing resistance high corrosion resistance and high tenperature resistance | Wearing and corosion resistance |

| Application | PE pipes, PVC, PPR, wood and plastic, XPS estruded plate, wire and cable, blown filmmachine, recycled plastic, etc | PE pipes, PVC, PPR wood and plastic XPS extrusion board, blown filmmachine, recycled plastic, etc |

|

|

|

|

|

|

|

|

|